Dyson has selected Singapore as the manufacturing centre for its first electric car.

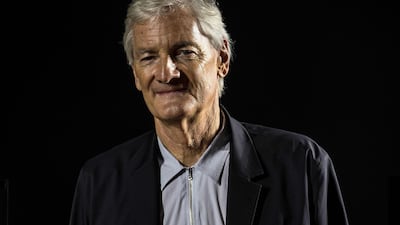

It’s a significant move in a number of ways: Dyson doesn’t yet make automobiles; it will base production in a city where no automobile manufacturing plants currently exist; and Singapore has a population of only 6 million and isn’t much of a car market. But founder James Dyson’s comments - and the company’s product paths to date - could hint at the future of electric transport.

My first thought: labour costs don’t seem to matter that much to the company. Singapore is hardly cheap, and if the priority was to be in Asia but not China, then other countries in South East Asia would fit that bill.

My second thought: starting from a purely electric drivetrain puts the company’s “centre of gravity” (in James Dyson’s own words) on new supply chains. Chief executive Jim Rowan said in a note to staff that the Singapore decision is “based on supply chains” and that “the availability of the expertise” there will be helpful to the company. That expertise, though, isn’t automotive; it’s in batteries, electronics and motors (rather than engines). A moving supply chain doesn’t exempt the company from the various automotive woes” that Tesla’s Elon Musk is so fond of talking about - production and delivery are still crucial - but a purely electric platform does create new possibilities, just as it did years ago for Tesla.

My third thought: Dyson’s experience with its vacuum product line shows us how much batteries and motors can improve in a relatively short period of time. With the launch of its latest handheld model, the V10, Dyson said it will no longer make vacuums with a cord, claiming that cordless models are as good as, or better than, ones that plug in. Twelve years ago, the company’s “digital motor” weighed about one-third of a pound and produced 85 air watts of suction power; today, the motor weighs a little more than a quarter of a pound and has more than three times the power at 290 air watts.

_______________

Read more:

BMW shifts into electric batteries and cost sharing on autonomous vehicles, exec says

Dyson steps up a gear with £2bn electric car production plan

_______________

Listen:

Business Extra podcast: ADCB merger would shake up banking sector

_______________

Lighter and more efficient systems like this are category creators. That combination of power in the battery and output in the motor allow the creation of a cordless vacuum. Improve them further, and that same system becomes a category killer: it kills off the incumbent offering - in this case, the corded vacuum models offered by the same company. It’s worth thinking about how this will play out in transportation. Which company will be the first to switch from making one or a few electric vehicle models (with two, three or four wheels) to making only electric vehicles?

Final thought: just like a vacuum, an electric car is in its own way a cleaner, too. Every electric vehicle on the road means one less source of street-level emissions. Electric vehicles are also, in their way, self-cleaning in a way that internal combustion engines aren’t. As the emissions intensity of power generation in an electricity grid falls, so do the emissions associated with charging an EV. Take Denmark, the UK and Finland and their declining carbon emissions from power generation: an electric vehicle plugged into the UK’s electricity grid in 2013 had twice as much carbon dioxide emissions per unit of electricity generated as it does today. Over four years, the same vehicle is responsible for half the emissions it once was, without the vehicle itself changing at all.

Electric vehicles get cleaner as power-sector emissions decline; cities get cleaner (and quieter) at street level, too.

Bloomberg