From towering carbon fibre gateways to bulky machinery, it has taken a mammoth operation to transport equipment from across the world to get the Expo 2020 Dubai site ready.

Trailer trucks with special permission moved extra-long building material on motorways in Europe by night. Special cargo planes were hired to carry heavy projectors made in Mexico.

Everything from construction supplies for futuristic buildings in the Dubai South area to high-tech robots that will greet visitors has reached the site over the last three years.

Alan Williams, UPS vice president Expo 2020 sponsorship and operations, gave The National a glimpse into the critical work behind the planning, management, tracking and delivery of a world fair.

The global logistics company handled the massive task of delivering the requirements of more than 190 participating countries.

Inside the company’s sprawling warehouse in Jebel Ali Free Zone, a large section is stacked with hundreds of thousands of crates and boxes marked for delivery to Expo.

At another warehouse on the Expo site, four 12m shipping containers have been modified to store goods that can be dispatched quickly in an area spread over the equivalent of more than 600 football fields.

The company drew on its experience as the official logistics provider for the 2012 London and 2008 Beijing Olympics.

Massive carbon fibre gateways from Bavaria

Transporting the 21-metre high portals that overlook three Expo entrances was the biggest single logistics project of the event and spanned multiple countries.

“It was one of the most complex supply chains that I have ever been involved in,” said Mr Williams, who has worked with UPS for more than three decades.

“We had to put in place specialist equipment, extendable trailers … Due to the length we had to get special permissions to drive from Germany up to Antwerp.

“We could drive only at night time on the autobahns with escort vehicles. It was very spectacular but also very challenging."

The wire mesh-like gates were carefully placed in trucks for the 780km road trip from Bavaria, in southern Germany, to the port of Antwerp.

Packed in wooden crates, the Arabic mashrabiya-style structures designed by British architect Asif Khan were then shipped from Belgium to Jebel Ali port.

The company moved one consignment a month and it took nine shipments in 2019 for the three sets of gigantic doors to reach Dubai.

Heavy equipment from Mexico

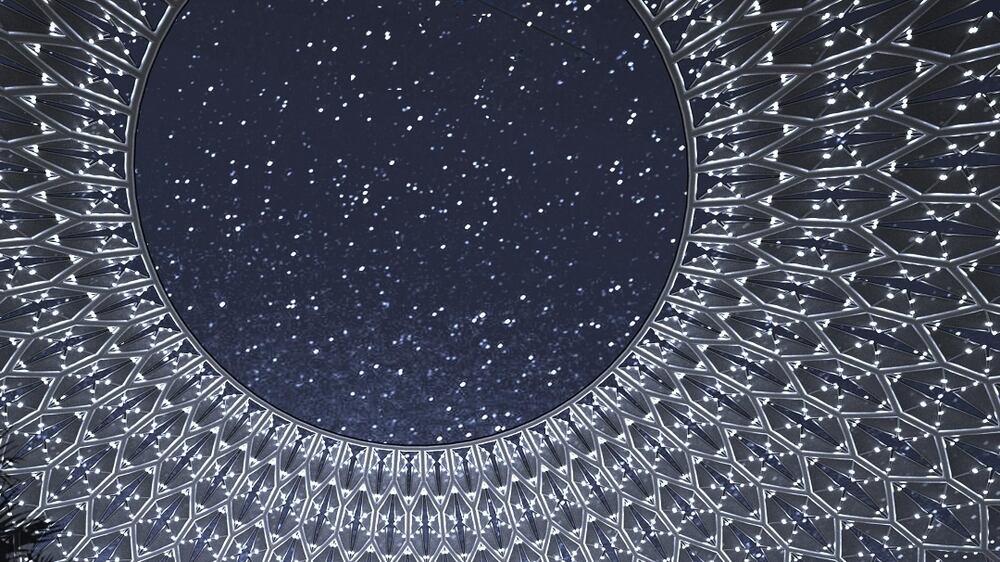

The world’s biggest cargo aircraft was chartered several times to deliver 11 projectors. The devices are crucial to beam images at night onto Al Wasl, the 360-degree steel trellis dome.

Each projector weighing more than 46 tonnes was lifted into the belly of the planes under expert supervision.

Manufactured in Monterrey, Mexico, the projectors were transported by road to Houston, Texas, and flown to Dubai.

“Due to their size and packaging, these were too big to go in a UPS aircraft, so we actually chartered an aircraft, the largest cargo aircraft in the world, from Houston to Dubai and then flew into DWC airport,” Mr Williams said.

“It sounds simplistic, five shipments in total, but it took a lot of planning.”

The dome, called the crown jewel of the Expo, will be the venue for the opening ceremony.

It will be the space for art shows and music performances during the day. At sunset, the translucent dome will be illuminated with images beamed by the projectors.

Robots and electric quad bikes

Expo officials have previously said that more than 100 robots will greet visitors, deliver food, help with directions and take photographs.

Opti, a golden robot known as the guardian of the Opportunity Pavilion, is an Expo mascot.

These robots, manufactured in China, were among high-tech machinery transported to the Dubai site.

UPS will showcase a four-wheel e-quad and a three-wheel e-bike to the public as part of its plan to use these later in crowded cities.

“The concept behind this vehicle is to operate in pedestrianised areas,” Mr Williams said.

“The width, length and safety features around the actual bike itself are aimed to operate it safely in industrialised areas.”

The rider can pedal the bike and batteries will kick in in case of a slope or a heavy load. Pedalling also recharges the battery.

Pandemic preparation

The coronavirus pandemic has shown how preparing for a health crisis should be part of disaster planning, said Mr Williams.

“The ongoing Covid-19 pandemic has tested the resilience of supply chains, and logistics providers have needed to urgently adapt,” he said.

“Pandemic preparedness has gone from an experts' discussion in the side room of a government planning apparatus, to a whole-of-government, whole-of-world priority.

“A local, regional or global health crisis needs to be a routine part of disaster preparedness going forward.”

By working closely with countries ahead of time to work out which supplies must reach Dubai, the team equipment was in place across ports and airports.

They started with construction-related material, then moved to fit-out supplies for the pavilions and are now stocking interiors.

“My first time at the site was probably in the middle of 2016 and at that stage it was just a desert with a couple of trucks rumbling across,” Mr Williams said.

“So to come here now and see the portals, the amazing pavilions of countries and also the thematic pavilions, it’s just incredible. I find this exciting to see this rise up out of the desert.

“This is something that really motivates my team because it’s such a special event. It makes us really proud to be part of Expo 2020.”